Product change is a constant in the food industry and consumer packaged goods:

- New consumer needs and wants implies product formulas’ changes,

- Changes to suppliers and manufacturing processes lead to recipes and packaging’ updates,

- Regulations evolutions may affect formulation or claims, etc.

The consequences of a misguided change can be serious: thousands of unusable packaging, a failure to comply with regulations, and in the end a large amount of funds lost.

Change management : how do you avoid related risks thanks to a PLM?

A Food PLM software can help you optimize change management with features that simplify formula’s changes, such as:

- A change management process to control the evolution of a product, to master its impacts and to track its record – for example, a simple change on a semi-finished product can affect a hundred of finished products

- An automatic re-calculation system – for example, a bi-annual renegotiation of commodity prices will require updating calculation of costs across the portfolio

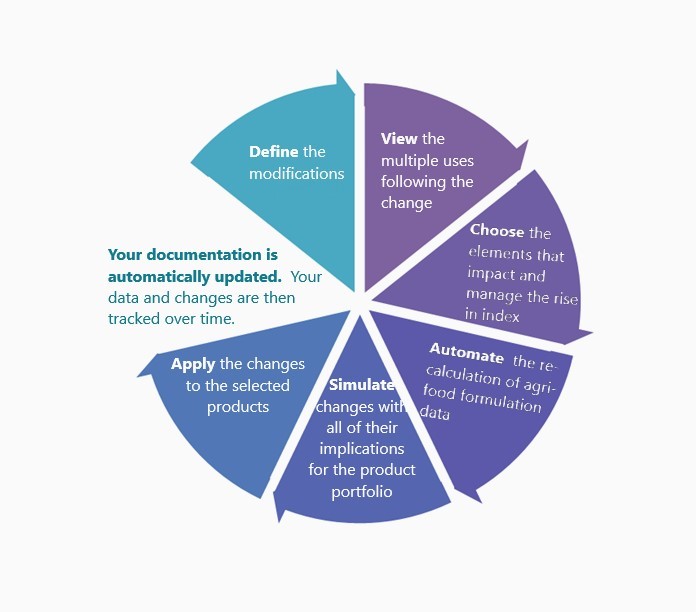

Here is an example of a change management process

With our change management functionality, R & D engineers can easily understand all the impacts of the considered changes, track data and changes over time, and automatically set up documentation updates.

Learn how Lascom CPG PLM software can help you optimize your change management!