PLM ERP are two major systems essential to develop and launch innovative and profitable products; therefore, it is important to understand their relationship. Indeed, ERP and PLM are complementary software that works together to ensure the success of a product. Product Lifecycle Management (PLM) comes first by managing the product development and its processes. Enterprise Resource Planning (ERP) manages the supply chain including the inventory, pricing, and payments. These are used sequentially to provide the most up to date product data at any time; however, there is also a continuous flow of information and data between the two platforms.

However, if one does not take a step back in order to see the bigger picture the two solutions, PLM ERP, may look the same and end up confusing instead of beneficial. The subject is therefore important and, below, we are going to go through the key points of these two tools.

ERP Software : What it is?

Let’s start with Enterprise Resource Planning (ERP). ERP enables companies to automate and support a range of administrative and operational business areas such as accounting, materials management, customer-facing. The objectives are to reduce costs and improve business process efficiency through easier information sharing and standardization. It boosts business intelligence and provide better customer service capabilities.

PLM Software : What it is?

PLM, or Product Lifecycle Management, is designed for manufacturers in the broadest sense – food and beverage, cosmetics, discrete manufacturing, etc., and aims to optimize the management of products throughout their life cycle, from idea generation through design and manufacture to disposal. Companies are able to manage their product development and innovation in a more efficient and cost-effective way.

ERP vs PLM: What are the différences?

The difference between the two systems (i.e.: PLM ERP) is detected within the managed data. In other words, even if ERPs add functions similar to those of a PLM, the central information managed is not the same:

- ERP focuses on physical assets and material flows such as production scheduling, inventory management, and shipping logistics; whereas,

- PLM focuses on the composition and interdependence between the different components of the products and the management of the “product environment” such as traceability, innovation, and management.

PLM and ERP: The two together

Metaphorically, they are just like the human body. Which has over 600 muscles and 200 bones. The muscular and skeletal system are both equally complex just like ERP and PLM and necessary together in order to accomplish the tasks at hand efficiently.

They share raw material or ingredient information, plans for the future of the product, regulation information as well as product information, in order to be complementary tools. The functional perimeters and their strengths depend directly on the data they manage.

By centralizing technical information in a common knowledge base and synthesizing key data, a PLM enables users to better understand information globally and thus foster innovation and collaboration between all stakeholders, both internally and externally. However, it does not have the objective of managing flows of articles and notions of stocks and logistics; which is related to an ERP.

In addition to the benefits a PLM provides inherently, it also reinforces the advantages of an ERP by allowing a unified management of all technical data. ERP, therefore, relies on the knowledge of the product and its environment provided by the PLM to optimize the flow management for manufacturing and logistics and to have reference product data.

ERP without PLM struggles to organize product record and may mismanage product changes as well as be inaccurate with financial planning. PLM is the starting tool that ERP must follow. That is why if an ERP tool is not integrated with a PLM solution and vice versa, you will not have their full optimal capabilities.

The best way to remember them: PLM = Virtual Product and ERP = Physical Product. Having a successful PLM ERP integration increases the capabilities and benefits of each system.

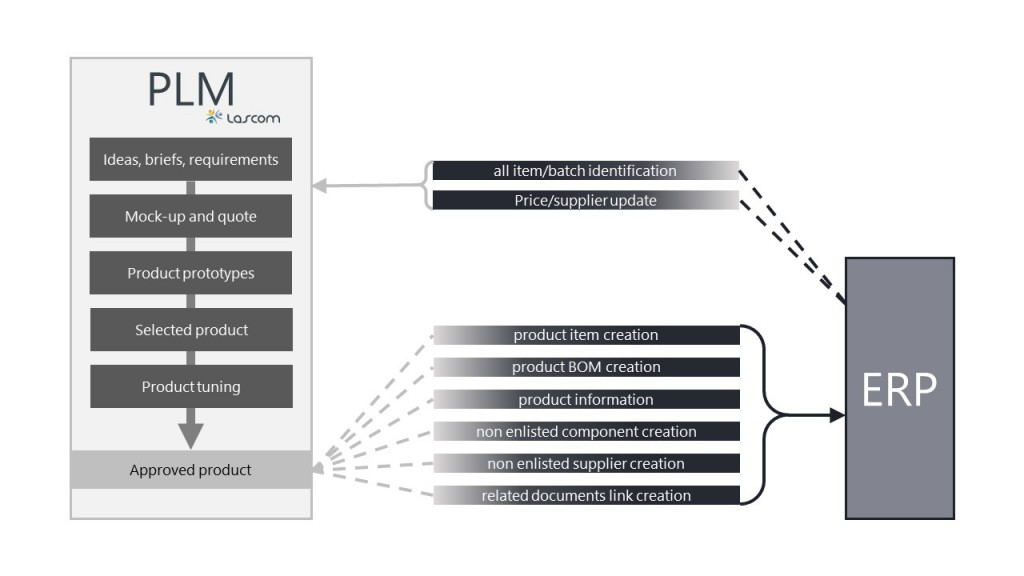

PLM ERP integration : two complementary software

There is no choosing between ERP and PLM, both are necessary, the choice will, in fact, deal with how to integrate the two applications. The two tools relate to the products and are necessary in order to provide a “single version of the truth of the product” to limit the errors of re-entry, and to follow-up versions of documents and products evolving in parallel.

This is why Lascom has developed partnerships with ERP vendors and provided standard connectors to facilitate integration between the two tools. With this integration, businesses are more agile and more reactive in all its activities (deliveries, quality, cost, traceability, innovation, etc.). And in the end, it fits the need to break down information within the company and facilitate sharing and collaboration!

Contact us if you would like more information.