You have a project?

Ask questions about Lascom products to our team of experts; we will be glad to answer you as soon as possible. Express your needs and expectations; we will do our best to organize a meeting with our sales team.

Food allergens are a real concern in the US. According to the FDA, about 2% of adults and 5% of infants and young children suffer from food allergies. Each year, it is estimated that approximately 30,000 people need emergency room treatment. For the same period, food allergies cause the death of about 150 individuals. With millions of Americans affected by food allergies, it is crucial for the food and beverage manufacturers to, firstly, understand what exactly food allergens are; and, secondly, implement processes to control and manage all types of allergens in their products.

The Food Allergy Research & Education describes a food allergy as a medical condition that results in an adverse health effect caused by the exposure to food triggers. Medically, the food proteins generate a reaction, where the immune system attacks these harmless proteins. The signs and symptoms vary from one individual to another. The allergic reaction can be mild (e.g.: itchiness, few hives, etc.), severe (e.g.: vomiting, trouble breathing, etc.) or life-threatening. As there is no cure for food allergies, one solution to avoid any reaction is to be extremely cautious about the food consumed. Through accurate and clear food allergen labeling, food and beverage manufacturers play a key role in helping consumers make safe choices. Despite the importance of food labeling, there is still room to improve processes in place to ensure products are accurately displaying any major food allergens.

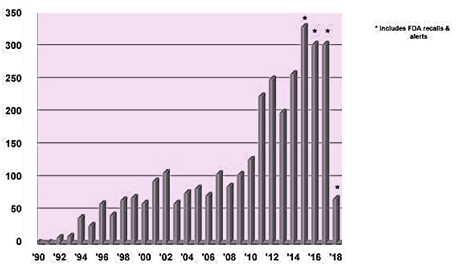

The graph below shows an increase of food allergen recall incidents until 2016 with a significant drop in 2017-18. Even though the number of incidents dramatically decreased from 2016 to 2017, it is still important to note that more than 50 incidents have been reported for the 2017-18 period:

Despite a decrease of recalls, the impacts of food allergens are still important. According to Dr. Li Zhou, over the last decade, there has been an increase in food allergy-related hospitalization in the USA. In total, the food allergies are estimated to cost the United States, approx. $25 billion per year.

Under the Food Allergen Labeling and Consumer Protection Act of 2004, these 8 foods and ingredients that contain protein derived from one of them are subject to FALCPA labeling requirements. In other words, allergens other than these big 8 are not subject to the labeling requirements. However, for allergic individuals, the sole protection is the product label.

Under the Food Allergen Labeling and Consumer Protection Act of 2004, these 8 foods and ingredients that contain protein derived from one of them are subject to FALCPA labeling requirements. In other words, allergens other than these big 8 are not subject to the labeling requirements. However, for allergic individuals, the sole protection is the product label.

Undeclared allergens on the product packaging has been identified as one of the main recall reasons. In 2017, 218 food products were recalled because they did not properly displayed allergenic ingredients on product labels. Cross-contamination with allergens is also another major cause for product recalls. However, simple steps can be taken to avoid these recalls and keep customer confidence high:

Information is key to ensure that all food allergens are properly identified. However, product development generates a high volume of information, and it can quickly become overwhelming to efficiently handle all this information. So, every data, especially food allergens data, should be gathered in the same place. A knowledge base or repository can help manufacturers centralize and structure this information, such as certifications and laboratory results. Creating a unique source of information will enable businesses to quickly access and find the right information at the right time.

The raw materials received from suppliers, but also how these supplier handle the ingredients in their own facility, will impact your final product and the allergens that need to be declared on your packaging. Therefore, it is essential to streamline communication with your suppliers. Few steps can be taken to enforce this relationship. The first one is to always structure the information received and send from/to your suppliers in the same way. This will facilitate information search as similar documents will follow the same structure. It will also ensure that all required information is received. The use of templates can simplify information sharing. Secondly, every time a supplier submits new information, it is crucial to immediately update the element concerned by the modification (e.g.: new traces of allergens). Information technologies can also help any food and beverage manufacturers to enforce their supplier relationships. A supplier portal can be implemented to improve collaboration. This portal will allow suppliers to directly input data such as raw material and ingredient specifications into the platform, guaranteeing timely and accurate information.

Do not wait for a recall or health alert to arise in order to enforce food allergens management. There are different options that food and beverage manufacturers can easily implement to be proactive:

Food and beverage manufacturers are concerned with food allergens, however, following those three simple tips will considerably facilitate allergen management. Discover how Aptean PLM Lascom Edition, a PLM software editor, can help you to, not only, manage food allergens, but also, ensure a faster go-to-market.